POWERTRAIN DESIGN

ABOUT

Powertrain Design

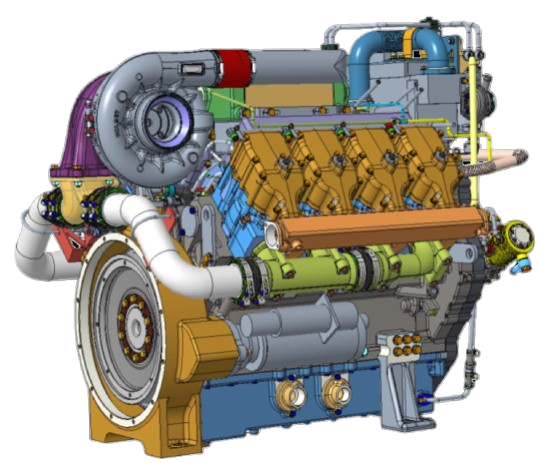

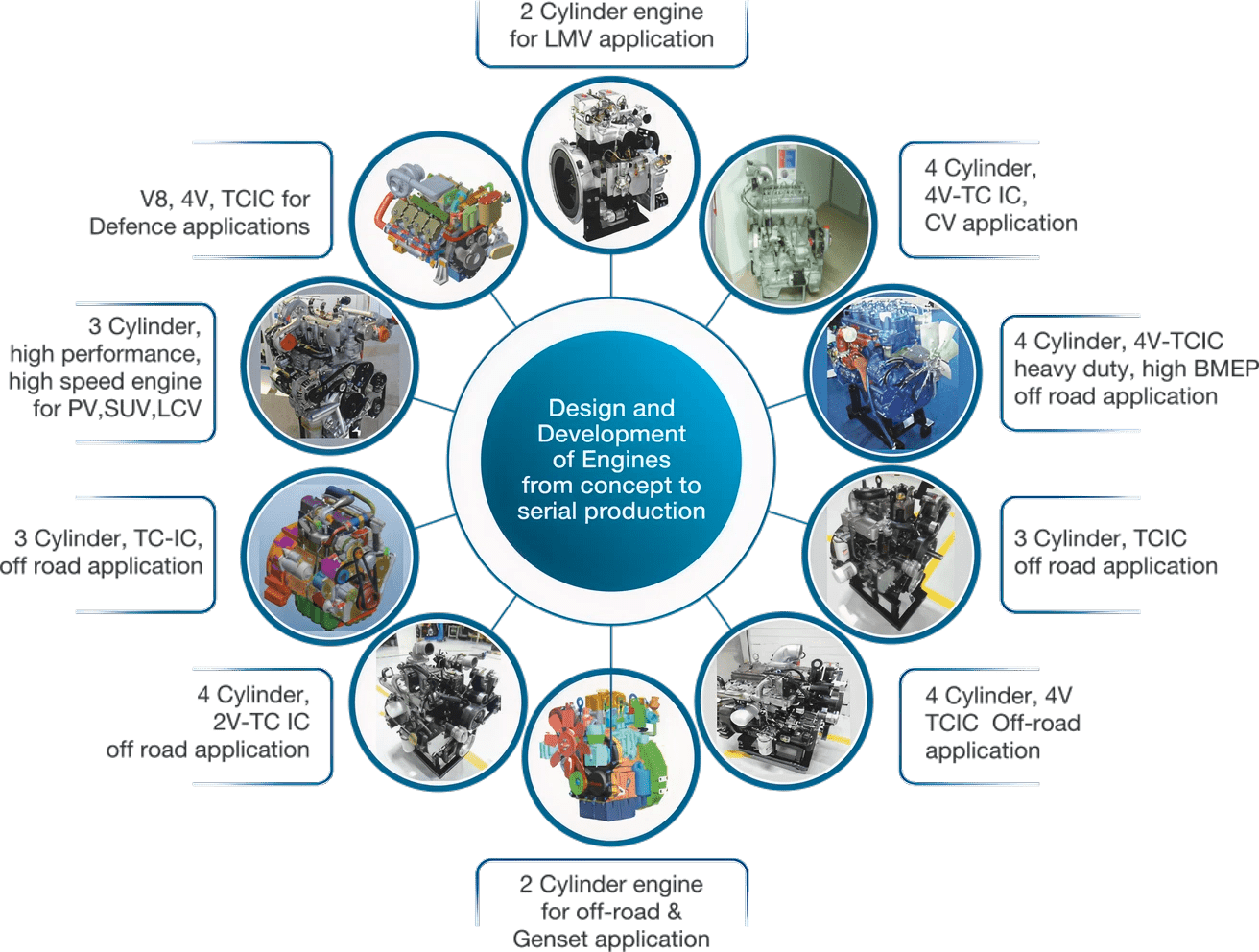

POWERTRAIN DESIGN (PTD) division of ARAI is an advanced R&D Centre for design and development of engines, transmissions and all kinds of axles including E-axles for PV/SCV/LCV/HCV. PTD is engaged in engine design from concept to prototype till serial production support for HCVs, LCVs, PVs, Utility Vehicles, Tractors, gensets, 2 & 3 wheelers, Defence & Power applications for meeting respective emissions norms, durability & NVH requirements On similar lines PTD have Competency to design all kinds of transmissions, axles, hybrid EV Powertrains, E-axles for PV, SCV, LCV, HCV & Hydrogen PEM Fuel cell electric powertrains.

Service Areas

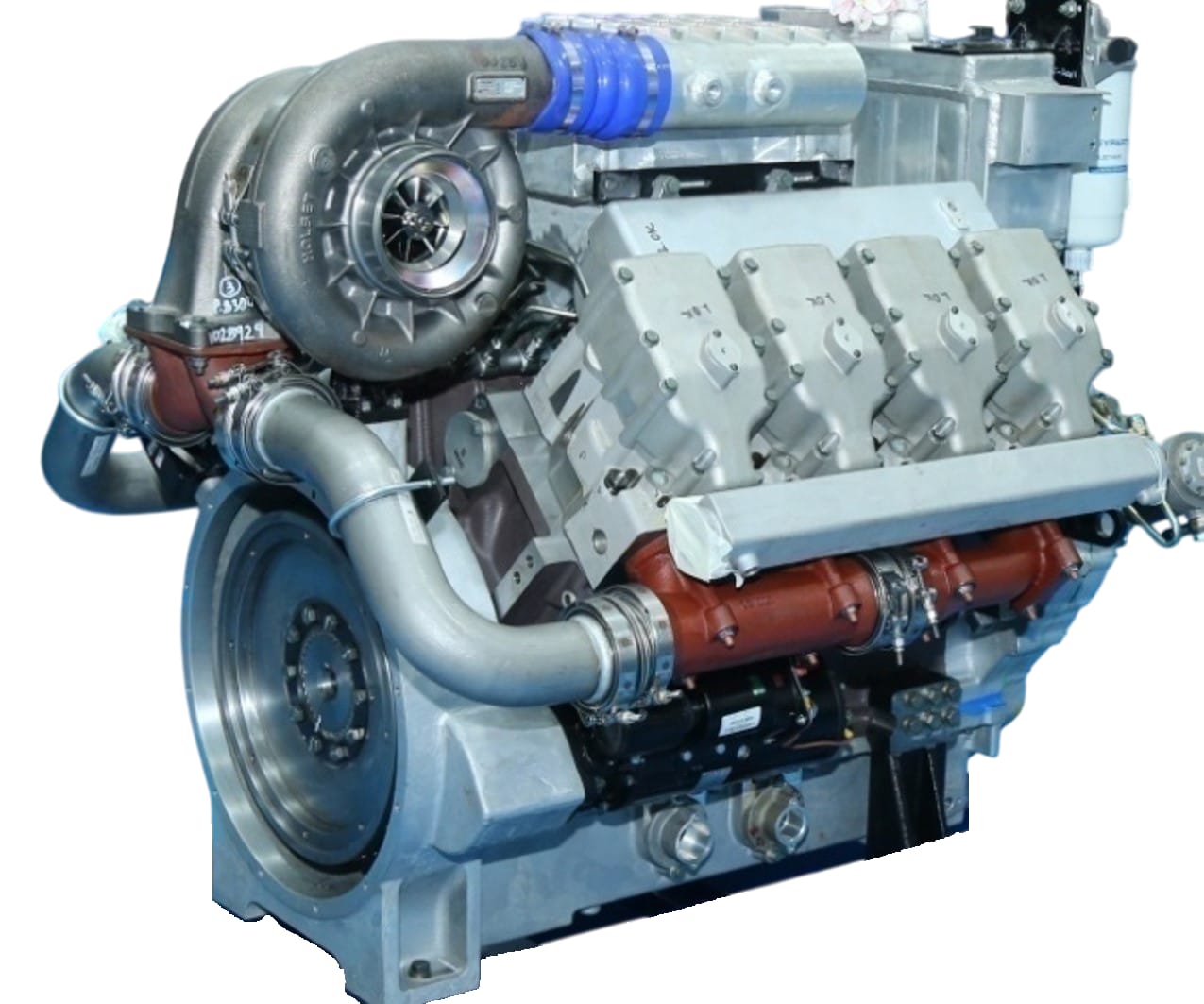

- Engine design from concept to prototype till serial production for all kinds of mobility & power generation applications

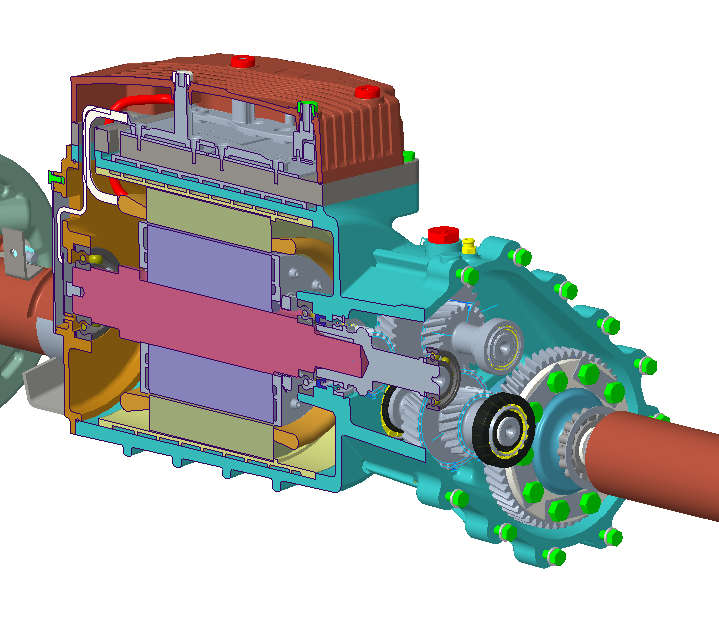

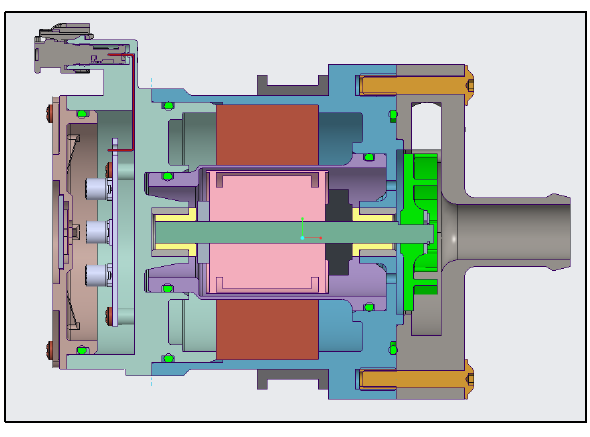

- Design of all kinds of transmission systems from concept to prototype till serial production for 2W, 3W, PV, SCV, LCV, HCV applications

- Design upgradation of powertrain systems & components (engine, transmission, driveline)

- Design vetting and feasibility analysis, benchmarking, CAD, FEA, CFD of engine, transmission & axle systems & components

- Support for supply chain creation & prototype development

- Design & development of electric axles for PV, SCV, LCV & HCV applications

- Design & development of powertrains for HEV, FCEV applications

- Design & development of hydrostatic transmissions

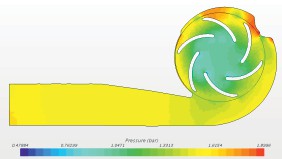

- Intake and exhaust port development

OUR EXPERTISE

Industries We Serve

Automotive

Automotive

Tractors & Farm Equipment

Tractors & Farm Equipment

Off-Road

Off-Road

Electric Vehicle

Electric Vehicle

Technology

Technology

Energy

Energy

Gensets

Gensets

Aerospace

Aerospace

Railways

Railways

Defence

Defence

Elevators

Elevators

Medical

Medical

Shipping

Shipping

Construction

Construction

AT THE HEART OF WHAT WE DO

Our Core Services

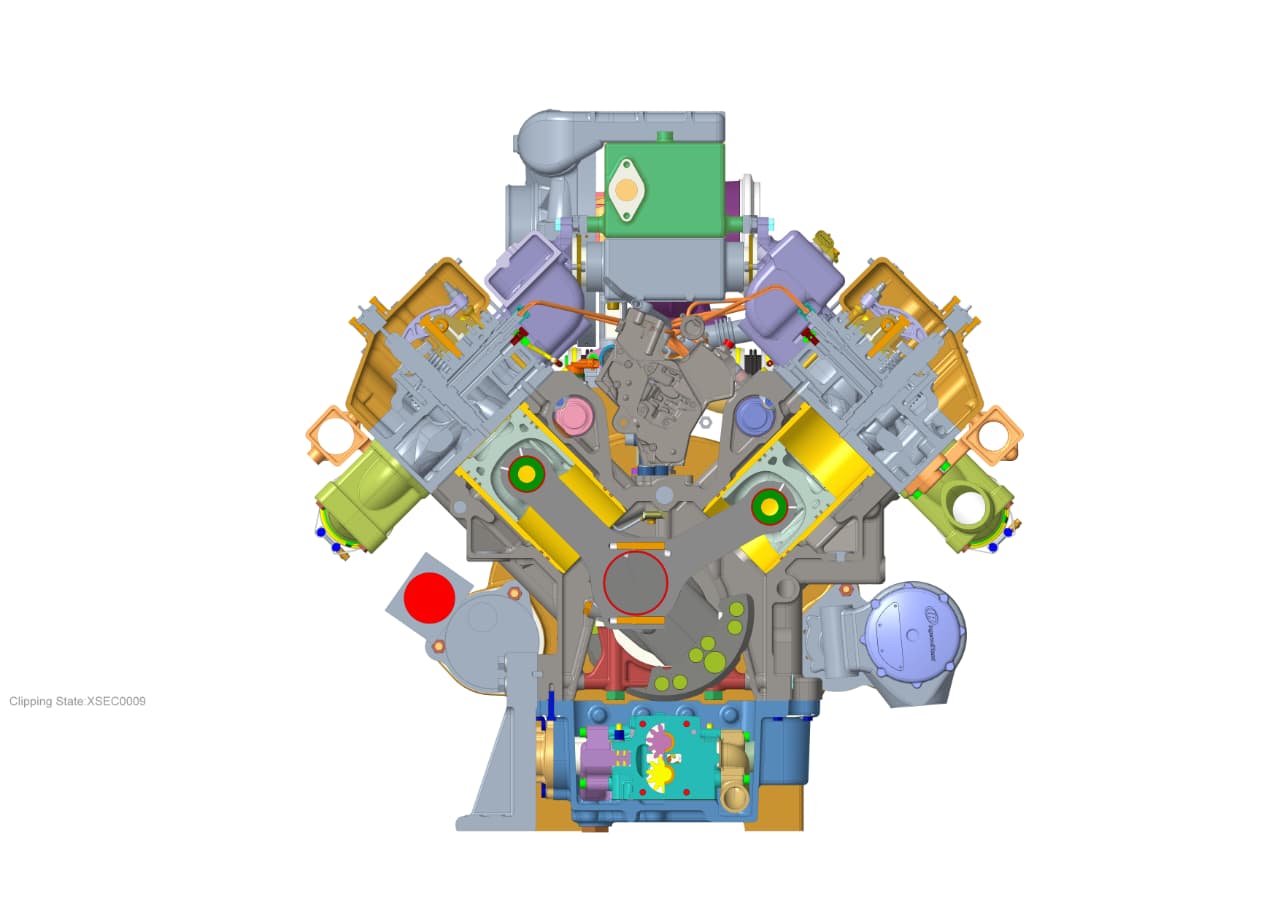

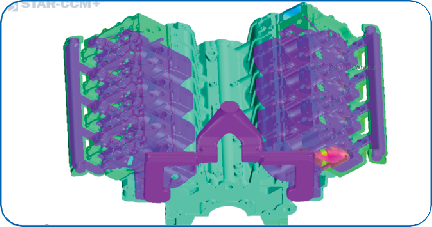

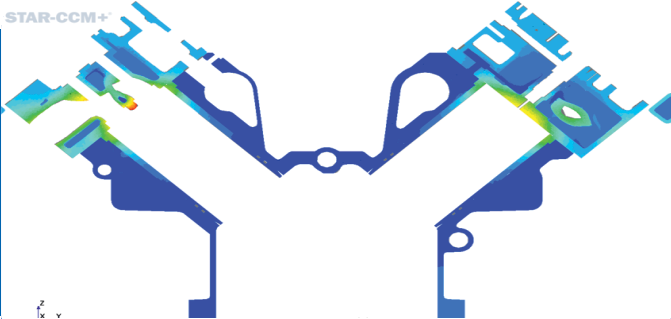

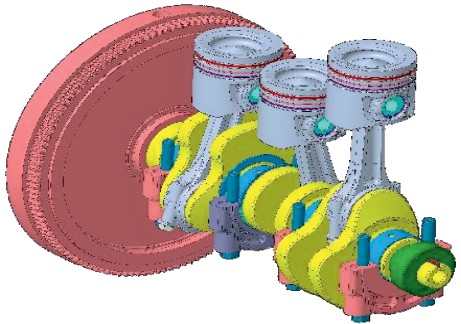

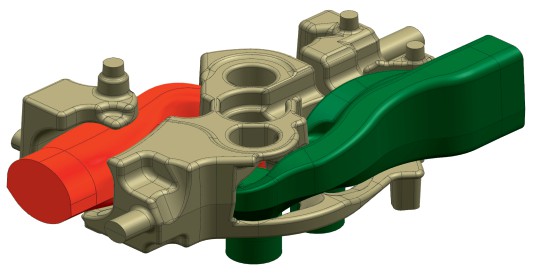

DESIGN/ANALYSIS OF SYSTEMS / COMPONENTS OF ENGINE

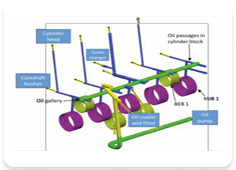

- Cylinder head, Engine block, Piston & Ring pack, connecting rods, Crank Shaft, Bearing, Damper Pulley, Flywheel, Oil Pump, Water Pump,

Camshaft, Torsional Vibration, Rubber / Viscous Damper, Cylinder Head, Gasket & Bolts. - Valvetrain system, Balancer shaft systems, Lubrication & Cooling System, FEAD & Gear trains, OCV & CCV System, Intake & Exhaust System.

- Kinematic & Dynamic analysis of valvetrain, 1D analysis of lubrication system.

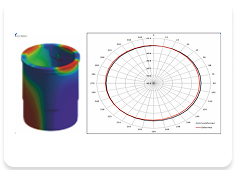

- CAD, FEA, CFD analysis of Engine system & components.

- Structural dynamics of Engine systems & components.

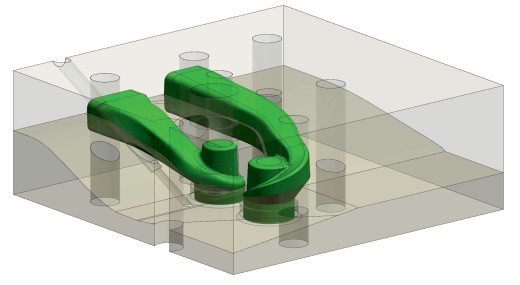

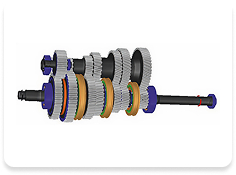

Design & Development of Transmission / Axles from Concept till Serial Production

- Transmission design for passenger vehicle, commercial vehicle, off-highway and Electric Vehicles

- Live axles including LSD

- Differential gear box

- Planetary gear box

- Analysis for gear whine, rattle, efficiency

- Transmission NVH

- Transmission error analysis & improvements

- Synchronizer sizing

- MBD for shift quality improvements

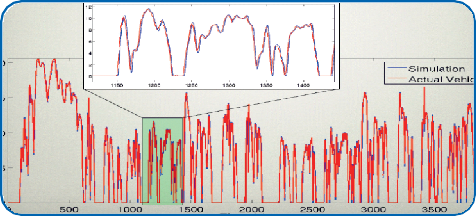

- Design and development of AMT controller

- Design and development of hydrostatic transmission

- Design and development of hydraulic lift and TPL for tractor applications

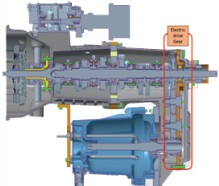

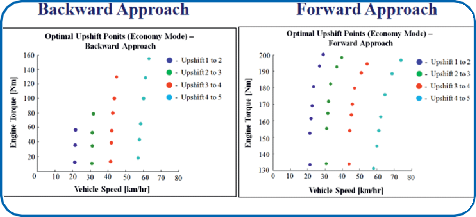

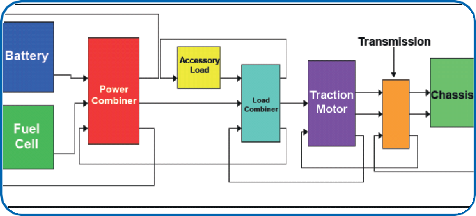

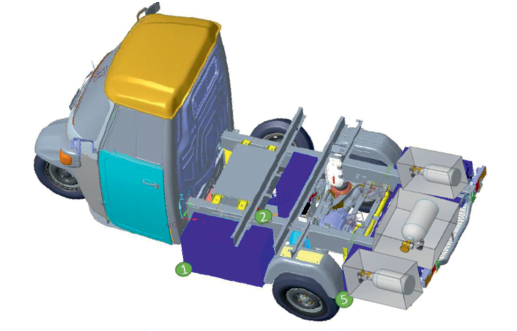

Design & Development of Advanced Powertrains (HYBRID ELECTRIC VEHICLES / FUEL CELL VEHICLES / E-AXLES FOR-SCV, LCV, HCV AND PVj

- AMT / DCT / CVT

- Layouting / Architecture & Configuration finalization for full parallel, mild, series hybrid EVs, Hydrogen fuel cell electric vehicles

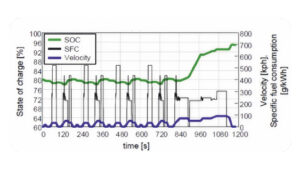

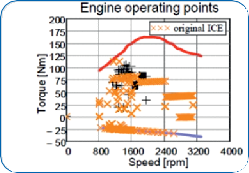

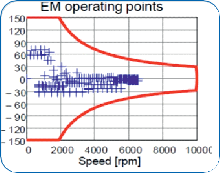

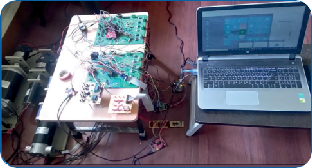

- Supervisory controller development for HEV operations

- Supervisory controller development for FCEV operations

- Conversion of EV to FCEV – Sizing & selection of hydrogen PEM / SOFC stack & balance of plant components

- Thermal / Coolant management of fuel cell engine

- Packaging and integration of fuel cell engine & hydrogen storage system

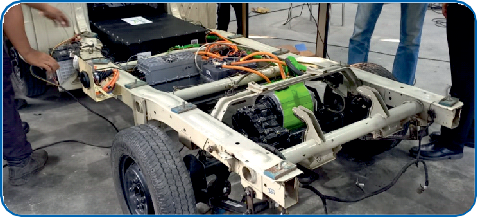

- Design and development of E-axles (SCV, LCV, HCV & PV)

- 2 Speed AMT based transmissions for electric vehicles

Electromechanical Design of Motors (IM / PMSM / SRM) integrated with E Axle and Auxiliaries

- Making of Indigenous PMSM for Electric Water Pump for EV Applications

- Making of 3 in 1 PMSM based E Axle for Small Commercial Vehicles

- Planed – Making of High Speed, Low Weight Induction Motor