INTELLIGENT VEHICLE TECHNOLOGY COE

ARAI as ADAS V&V Partner

- Aligned with Global Practices

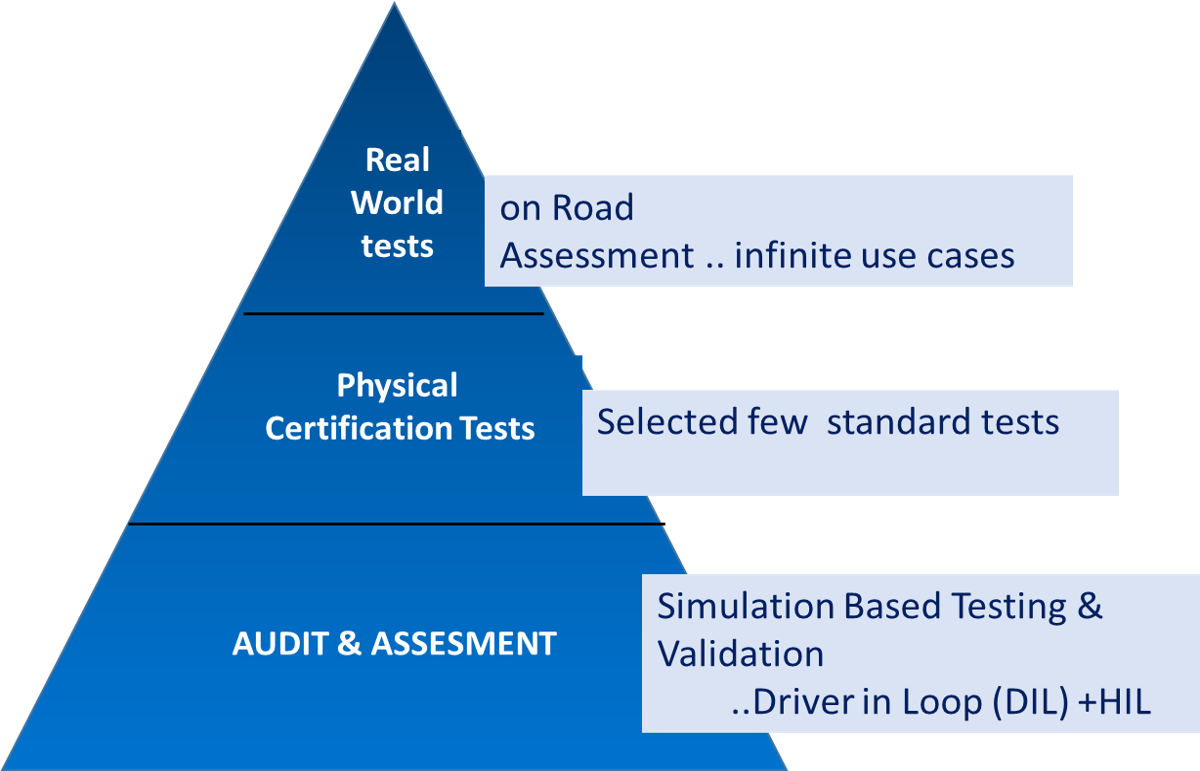

- Integrated Virtual and Experiential V&V Methods

- Testing as per International Standards and Regulations

- Validation & Calibration for India Specific Use cases

European & Indian Standards

| Sr.No | ADAS Feature | AIS | In-Line with | Applicable Vehicle Category |

|---|---|---|---|---|

| 1 | AEBS | AIS-162 | UNR 131 (Rev. 1, Amd 1) | M2, M3, N2 and N3 |

| 2 | Automated Commanded Steering Functions | AIS 193 | UN R 79 (Rev. 4, Amd. 6) | M & N |

| 3 | LDWS | AIS 188 | UN R 130 (Amd. 1) | M2, M3, N2 & N3 |

| 4 | Blind Spot Information Systems | AIS 186 | UN R 151 | M2, M3, N2 & N3 |

| 5 | Moving Off Information Systems | AIS 187 | UN R 159 | M2, M3, N2 & N3 |

| 6 | DDAWS | AIS 184 | (EU) 2021/1341 | M, N2 and N3 |

| 7 | ELKS | AIS 191 Part-1 | EU 2021/646 | M1 & N1 |

| 8 | AEBS | AIS 185/DF | UN R 152 (Supplement 5 to 00 Series of amendments)- | M1 & N1 |